SYS 491 - Senior Design

ME 492 - Senior Mechanical Engineering Design Project

Winter 2015

|

EE 491 - Senior Design SYS 491 - Senior Design ME 492 - Senior Mechanical Engineering Design Project Winter 2015 |

January 6, 2015

Winter 2015 Design Project Description:

For the Winter 2015 semester, we will develop designs for Leader Dogs for the Blind, a world-renowned organization dedicated to "empowering people who are blind, visually impaired or Deaf-Blind with lifelong skills for independent travel through quality Leader Dogs, highly effective client instruction and innovative services".

For the Leader Dogs for the Blind (LDB) projects, the following general procedure will replace the design/build/competition procedure described in the syllabus:

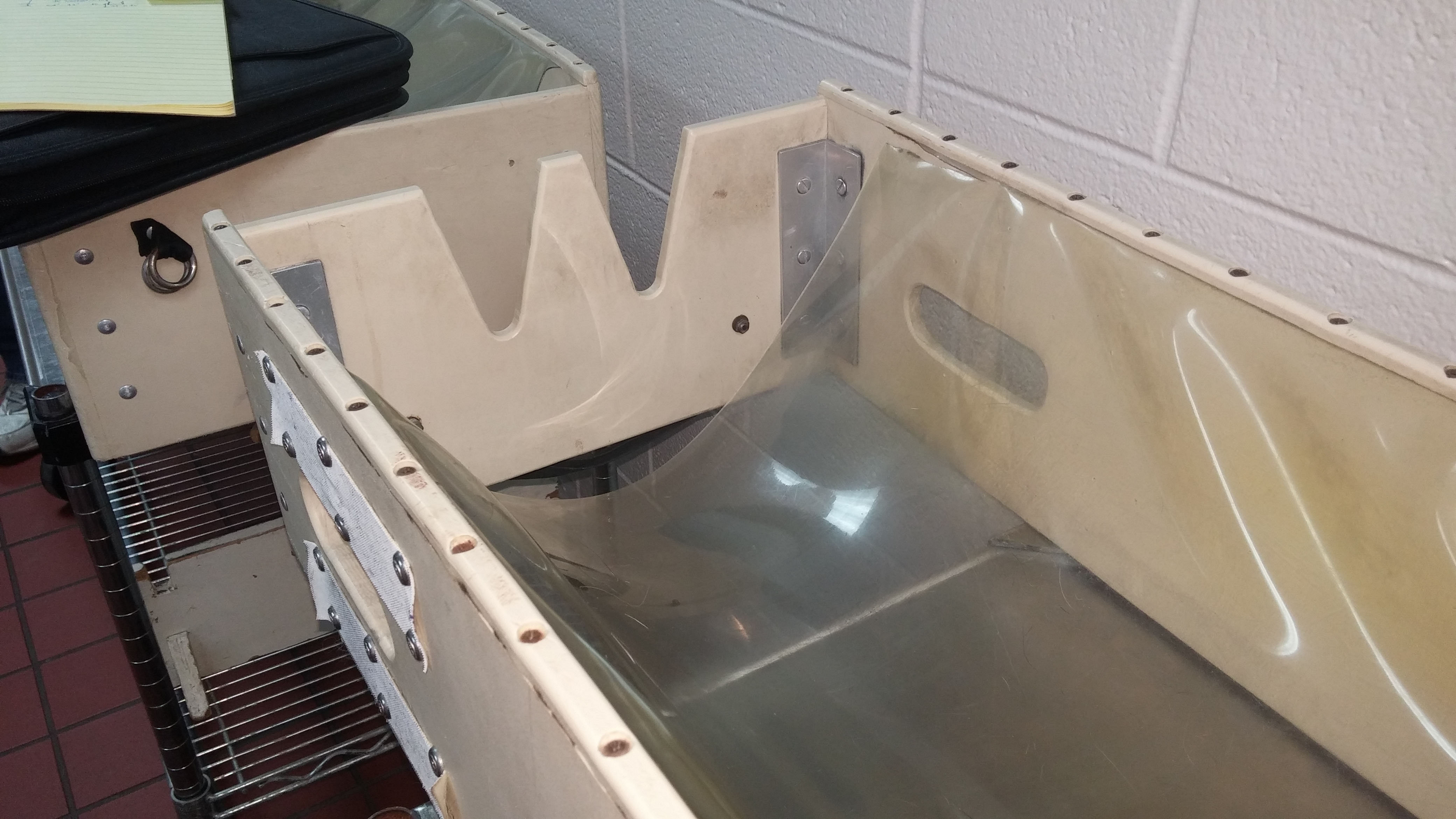

The photos above show the current device used to transport and position dogs for surgery and x-ray procedures. The anesthetized dog is placed spine-down onto the vinyl sling in the removable box, and its hind legs are positioned through the notches at the end of the box and secured. The entire cart is rolled into the OR for surgery. The box can be lifted off the cart and placed directly on the x-ray table. The following improvements are needed:

The photo above shows the current transport cart. It is basically a common hydraulic lift industrial parts cart with a dog bed attached. Large dogs seen by the LDB are 100-lb, more typical are dogs in the range from 60 to 75-lb. The following improvements are required:

Puppies less than 5 lb, and especially puppies born via Caesarian section, cannot adequately control their body temperature in the cold, making transport very risky in inclement weather. For socialization reasons, puppies need to be in physical contact with their litter mates, and should not be separated for long periods of time. Litters sponsored by the LDB are whelped at residential homes and periodically need to be transported to the LDB veterinary facilities.

There is a need for a litter transport unit. This unit must control the environment within the unit within 5° for an entire litter (1-7 puppies) during a 60-90 minute automotive transport. Fresh air flow in the unit must be maintained. The entire unit must be portable by two people, easily moved through residential doorways, be "laundry basket size," no more than 25" wide and 50-lb, including the puppies.

Sorting small parts is a common and costly task that manufacturing facilities are faced with. In this project, we will build small devices to sort small parts

The six (6) specific parts we will sort in this project are:

Competition: On Thursday April 21, 2015 (the study day) a competition will be held for all of the parts-sorting design groups, beginning at 10 am, in 178 EC. Each team will attempt to sort a bucket of parts, consisting of 20-30 pieces of each of the six different parts, in the shortest time. Incorrect sorts will incur a 5 second penalty. The score for each run will be the time, including penalties, multiplied by the cost of the device.

We anticipate an opportunity to test a new type of fastener for military applications. This test will take no more than 2 weeks and involve no more than 3 students. When the fasteners become available, the selected students will arrange to test them at the FAJRI facilities in Dodge Hall, write a report of their findings and present the results to the fastener company and military contractors. Due to the nature of this project, this opportunity is only available to US citizens.